PLUMSTEAD MAINTENANCE DEPOT & SIDINGS

PLUMSTEAD MAINTENANCE DEPOT & SIDINGS

Plumstead Maintenance Depot & Sidings (C695 & C696) were a crucial part of the Elizabeth Line programme. This facility was the last major project put into place by Crossrail & had been issued to ATC JV. This project was key for the future operation of the Elizabeth Line Train’s.

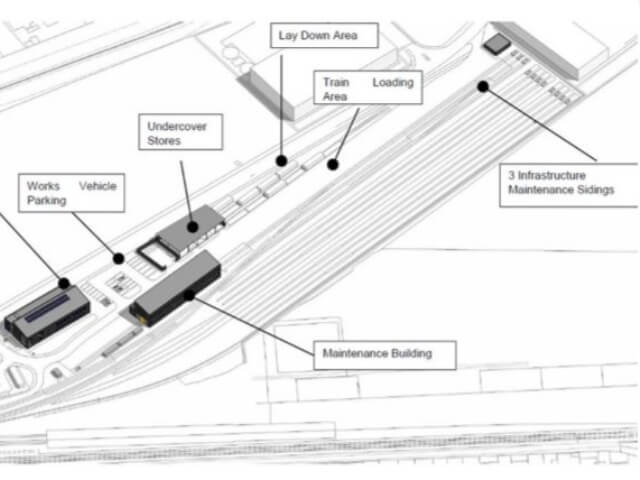

Key elements of C695 & C696 included:

• Track works: laying of the ballast track (4.5km) and special tracks (0.5km);

• Installation of 3.5km of catenary (25kV);

• Installation of electrical networks (lighting and CCTV): 4kms of cable routing;

• Civil engineering works: construction of access platforms to trains and 2000m2 of concrete slabs for the storage of spare parts (track devices, rails, sleepers, cables, etc.), road works, drainage of surface water (5km), creation of security fences, refuelling system;

• Construction of three buildings: a main building dedicated to maintenance teams (1000m2 on the ground, two floors), a building dedicated to work trains (1000m2 on the ground), a building dedicated to train cleaning teams;

• Training the teams of the future site user.

THE CHALLENGE

IPMA was brought on board in mid-way through the project by ATC to finalise the handover of C695 & C696 projects. As the physical build was ongoing, we picked up the handover & assurance documentation to progress this to completion & managing the day to day KPI’s, PTR’s (Project Technical Requests) & assurance process.

THE WORK

Working closely with the in-place ATC team we focused on the below to ensure delivery of the C695 & C696 project:

1. Progressing the handover and assurance documentation to completion & handover to the client Crossrail.

2. Implementation of streamlined documentation & review process, including client interface to ensure speedy & issue free acceptance.

3. Enhanced client interface & updates to progress concerns & satisfy contract requirements & gain acceptance.

4. Delivery of milestones to allow Trail Running under ROGS (Railway & Other Guided Transport Systems) which kept the Crossrail Programme on schedule.

THE RESULT

Our work ensured the streamlined handover of C695 & C696 in the following way:

1. Minimised delay on installation and assurance paperwork.

2. Acceptance of systems on time.

3. The creation of a positive environment as a result of delivering the correct assurance documentation.

4. The promotion of a more collaborative approach.