BOND STREET STATION – ELIZABETH LINE

BOND STREET STATION – ELIZABETH LINE

IPMA CEO Keith McDaid led a team of specialists on this project at one of the UK’s busiest railway stations in the heart of London’s shopping district.

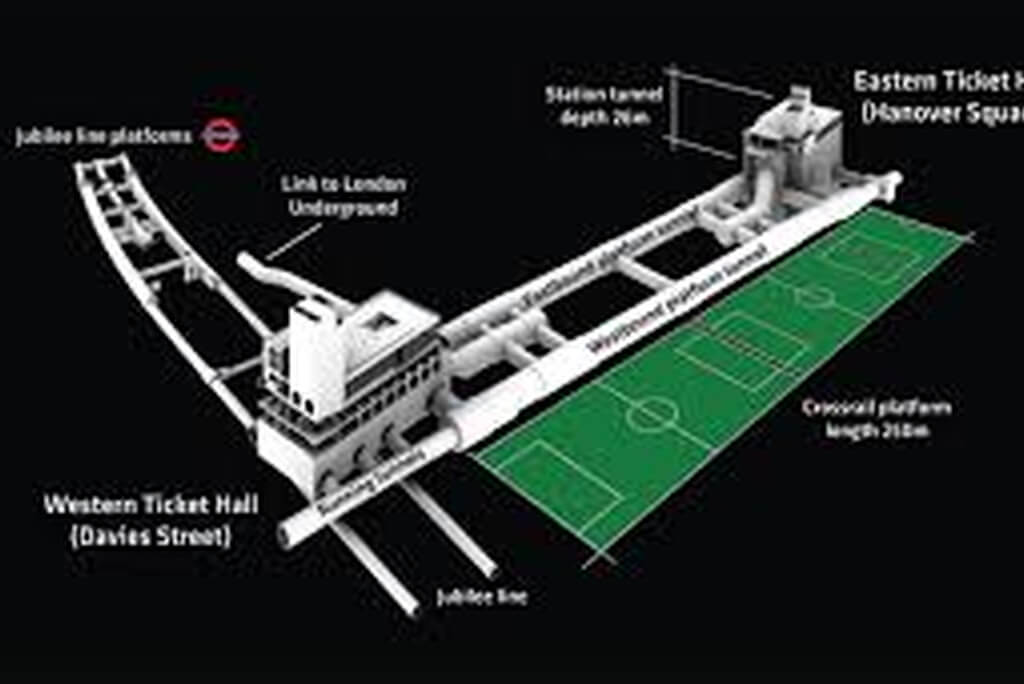

The Bond Street project will deliver a major new Elizabeth Line station, substantially increase station capacity at this busy central London location and support 24 Elizabeth Line trains an hour running in each direction at peak times.

Key elements of the C412 project included:

- Building and structures works.

- Surface water drainage and utilities.

- Mechanical systems (HVAC, chilled water, etc.).

- Electrical systems (Dali lighting, power distribution, lightning protection etc.).

- Fire suppression and alarm (fire alarm panels, gas suppression, water suppression).

- Public health systems, drainage systems (pumped and gravity), sump systems etc.).

- Installation of communications equipment and materials

THE CHALLENGE

IPMA was entrusted with completing the main MEPH handover of services for the western and eastern ticket halls, as well as the link tunnels connecting the ticket halls, within a revised budget and strict time frame to completion. IPMA appointed a team of discipline-specific handover specialists to achieve the handover of Bond Street Station within the revised milestones.

THE WORK

Work completed included:

- Implementation of a new MCR process. This aided the assurance process for traceability and approval of equipment that had been installed and enabled the client to accept the installed works. This was relatively quick and easy due to the team’s dedication to clear communication with their counterparts in CRL at Bond Street, as well as having readily available compliant materials lists which were developed during previous similar projects.

- IPMA next turned its focus to the design element of works on the project to ensure that the installations could be assured against the design, and to capture buildability issues and design changes. These were recorded as part of the handover documents.

- IPMA enhanced the existing the package structure breakdown to demonstrate to CRL how the project would be handed over in a more streamlined process. This also had a secondary effect on the commercial element of the project and demonstrated the logic behind the staffing levels required to complete the project in the given time frame.

THE RESULT

This ensured the streamlined handover of station systems in the following ways:

- Minimised delay on installation and assurance paperwork.

- Acceptance of systems on time.

- Created a positive environment as a result of delivering the correct assurance documentation.

- Promoted a more collaborative approach.